In shipbuilding, one thing is essential: safety and control in every situation. Whether luxury yacht, naval ship, research vessel, or submarine – modern ships place high demands on technology, reliability, and maintenance. An essential component is wave brake systems, which ensure safety with their diverse functions and increase efficiency on board. Even more powerful today is what emerges from combined expertise:

With the merger of ATEK Antriebstechnik Willi Glapiak and the renowned Deutsche van Rietschoten & Houwens into ATEK Drive Solutions in 2024, competence, experience, and innovative strength for the development and manufacture of individual wave braking solutions for all types of ships and applications are pooled.

In this blog article, you will learn why the Elephant Brakes from ATEK Drive Solutions are the first choice in the maritime world. We will show you how wave brake systems “Made in Germany” fit your ship’s vision and what to consider when selecting and installing them.

Every ship presents its own challenges for safety: high-sea yachts, research vessels, or fisheries protection boats operate in extreme climatic conditions, demanding absolute reliability – and maximum control over drive and drive components. This is where ATEK’s customized wave brake systems come into play. Everything from a single source – from the initial design through planning and manufacturing to maintenance, adaptation, and service.

The advantages of these individually tailored solutions:

Always up to date with the latest technology, through:

After the merger of the two companies and the renaming to ATEK Drive Solutions, full energy for the development and realization of complete wave brake systems for ships is pooled in Rellingen, Schleswig-Holstein. The delivery times are short and far below market average. Furthermore, ATEK Elephant Brakes are available both as individual components and as complete prefabricated systems.

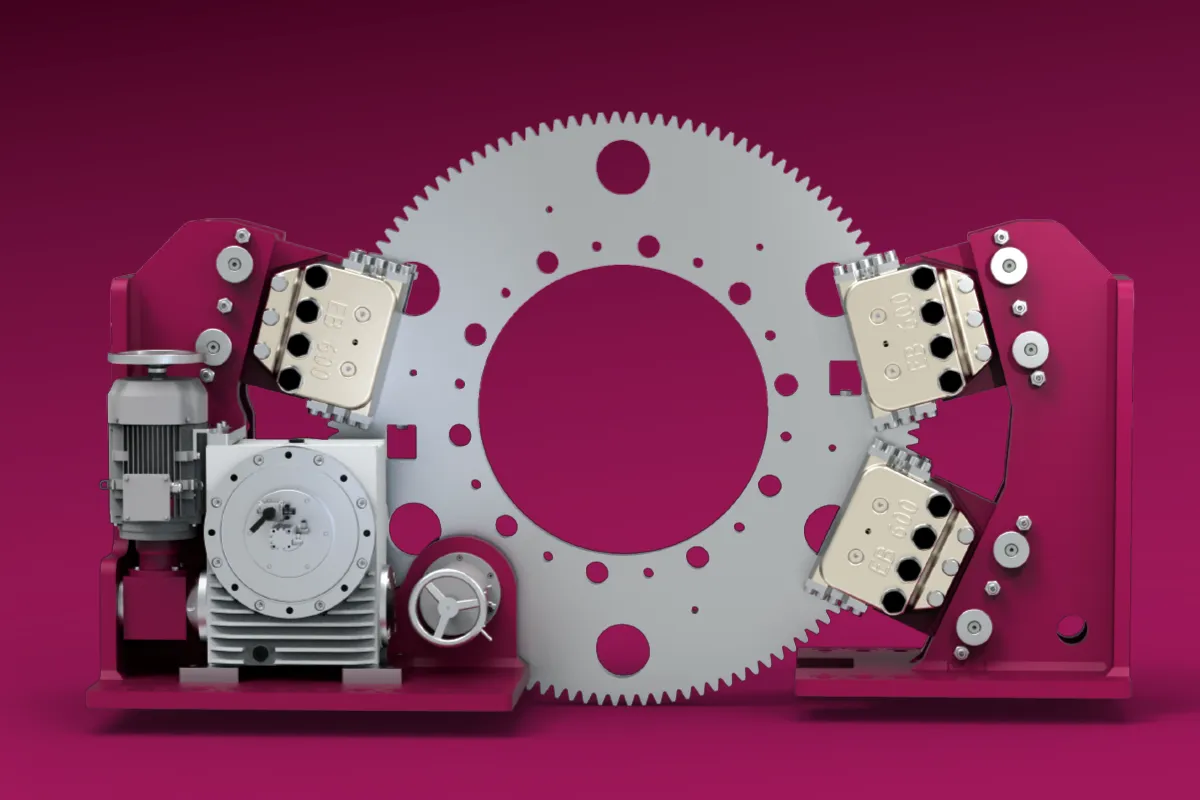

The classic wave braking systems combine three basic functions: Turning, Locking & Braking:

These functionalities can be combined and expanded according to customer requirements. ATEK Drive Solutions provides solutions ranging from simple and cost-effective to highly complex premium systems with extensive monitoring and remote control.

From idea to commissioning: You receive system solutions that are tailored exactly to your requirements. The service includes steel construction and complex piping as well as the design of hydraulic units, control technology, on-site installation, or painting according to individual color and quality standards.

Extreme maritime operations place the highest demands on technology and materials. The Elephant Brakes from ATEK Drive Solutions impress with:

Customers also benefit from short delivery times due to optimized processes and inventory management. The systems can be ordered as individual parts for easy on-site assembly – perfect for shipyards looking for flexible integration solutions.

To give you a sense of the performance spectrum, here are some practical examples from ATEK Drive Solutions’ recent shipbuilding experience.

Ship type | Braking torque | Locking torque | Brake disc | Features |

Research vessel | 370 kNm | 900 kNm | Ø 1536 × 65 mm | With turning gear and split design |

Luxury yacht | 150–370 kNm | 227–900 kNm | approx. 1500 × 50 mm | “Highest Yacht Standard”, special damping |

Naval ship | Up to 900 kNm | Up to 900 kNm | Custom manufactured | Shock-proof design according to BR3021 |

Submarine | Custom | Custom | Corrosion optimized | Extremely pressure- and saltwater resistant |

Jet propulsion system | Up to 370 kNm | As needed | Modular system | Space and weight optimization |

Typical installed systems include: wave brake systems with blocking device (e.g. 60 kNm braking torque), individual monitoring units (certified pressure switches, runtime monitoring) and a turning gear for moving the ship’s shaft during certain maneuvers.

From the design to the color scheme, Elephant Brakes by ATEK Drive Solutions are completely tailored to your needs. Every detail matters – from integration into overarching control systems to the finish for the highest aesthetic demands on luxury yachts.

Your advantages at a glance:

Innovations are only valuable if they function reliably over time. That is why ATEK focuses on well-thought-out processes and comprehensive quality assurance:

Wherever precise steering, safe blocking, or braking of the shaft/propeller is required, Elephant Brakes and wave brake systems from ATEK Drive Solutions are the first choice for luxury yachts (aesthetically and technically at the highest standard)

The synergy makes the difference; through the merger of our two German companies, not only is the concentrated know-how in the field of wave brake systems bundled under one roof, but also the innovative power of two market leaders in gear and brake technology.

Safety, efficiency, ease of use – modern wave brake systems are integration products of engineering, material decisions, and practical experience. Elephant Brakes by ATEK Drive Solutions combine these features to perfection. Whether you are planning a complete new ship design, a retrofit, or a single project, with customized Elephant Brakes you can count on:

Brakes: Rietschoten Elephant Brakes

Gears: Atek Antriebstechnik

Motors