ATEK Drive Solutions is currently working on highly integrated drive systems from a single source and is specifically expanding the motor area. We are in the development phase and are building a consistently coordinated overall system – from our own M-servo motor through the PCE planetary gears to future controllers integrated in the motor housing and suitable software. We will continuously inform about new developments and milestones in our news section. Stay tuned.

At the center of our roadmap is consistent system integration. The goal is to minimize installation space and increase power density, reduce interfaces, and take responsibility for the overall system from a single source. For our customers, this means: a central contact person from design to service, fewer transitions between components, lower tolerance chains, reduced cabling, and faster commissioning.

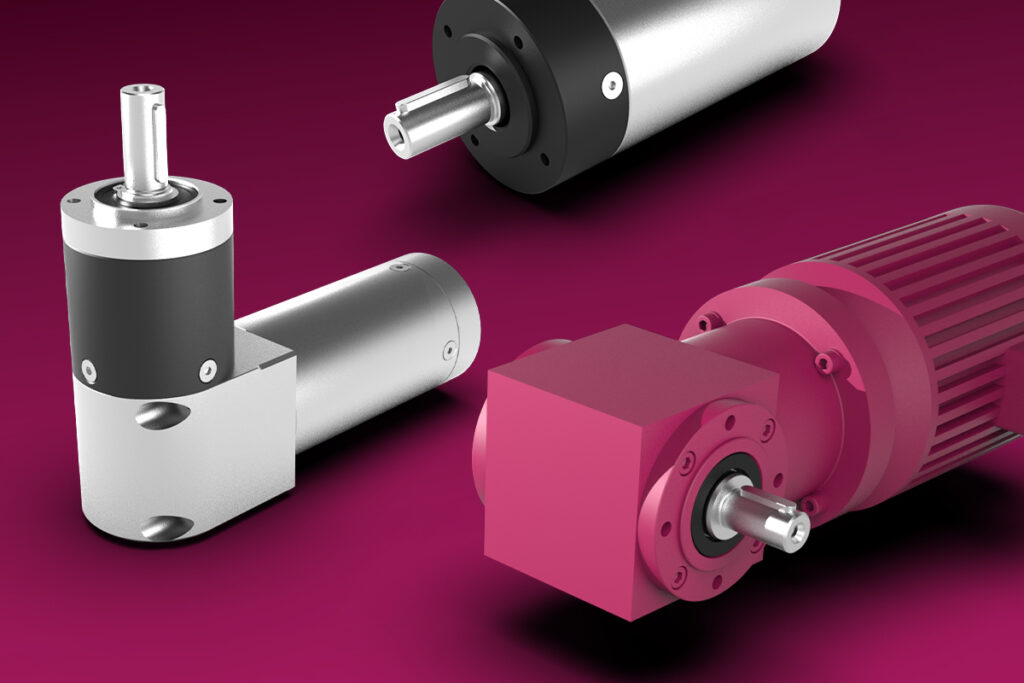

A dedicated motor platform is being developed with M type servo motors. A robust BLDC architecture with 24 V is planned, which, in combination with our PCE planetary gear series, leads to highly integrated gear motors. Gear ratios from 1:1 to 100:1 cover a wide range of applications – from dynamic direct applications to high-torque precision movements. Mechanically, we think uncompromisingly compact: without unnecessary motor flanges and couplings, with reduced inertia, less play, and higher stiffness. This simplifies assembly and lowers overall costs over the lifecycle.

Another building block for the coming years is the development of our own motor controllers, which are to be integrated directly into the motor housing. This creates a space-saving, environmentally protected solution with industrial-grade communication (planned: CANopen) and precise control for dynamic, reproducible movement profiles. To sustainably secure innovation and delivery capabilities, we are expanding our team and our infrastructure. Additional motor, hardware, and software developers are planned, as well as the establishment of a testing and measurement laboratory and new motor test stands to characterize efficiency, torque, dynamics, noise, and thermal behavior.

In the product portfolio, we anticipate the first standard sizes 40 and 60 from 2026; further sizes 80 and 120 are in preparation. The solution remains scalable: M servo motors and PCE planetary gears are coordinated to allow standardized interfaces on the application side and flexible configuration options on the system side. In addition to these standards, we plan custom variants at any time – from special gear ratios, shaft geometries, and mounting variants to adapted control parameters, firmware functions, and protocol extensions, as well as application-specific tests and documentation, gladly also within the framework of pilot projects.

Our goal remains unchanged: a well-integrated, compact, and powerful drive system with minimal interfaces and maximum reliability. Stay informed – we regularly publish updates in the news section – and contact us if you are interested in the planned standard solutions or if you want a tailored drive solution.

Brakes: Rietschoten Elephant Brakes

Gears: Atek Antriebstechnik

Motors