Hypoidgetriebe

Leistungsstarke Achsversatzgetriebe

Hypoidgetriebe sind hochpräzise und leistungsstarke Achsversatzgetriebe. Diese dynamischen Getriebe sind den hohen Anforderungen unserer Zeit in jeglicher Hinsicht gewachsen. Sie sind leistungsstark und kompakt. Nicht ohne Grund werden sie unter Anderem weltweit in der Robotik und für hochdynamische Anwendungen eingesetzt. Hypoidgetriebe sind umgangssprachlich auch bekannt als Kegelrad-Achsgetriebe.

Hypoidgetriebe gehören zu den Spiralkegelradgetrieben. Der Vorteil eines Hypoidgetriebes liegt darin, dass das Kegelritzel, durch den Achsversatz, mit einem größeren Spiralwinkel versehen wird. Dadurch steigt die Gesamtüberdeckung der Verzahnung. Aus diesem Grund sind Hypoidgetriebe in der Lage, bei gleichem Bauraum mehr Drehmoment zu übertragen. Daraus ergibt sich eine größere Anzahl von möglichen Übersetzungen und ein höheres mögliches Übersetzungsverhältnis.

Durch den hohen Gleitanteil in der Verzahnung lässt sich eine besonders hohe Laufruhe und ein sehr geringes Verdrehflankenspiel erreichen.

Typ H

Hypoidgetriebe

Merkmale

- Übersetzungen: i = 3:1 bis 15:1

- Maximales Abtriebsmoment 1450 Nm

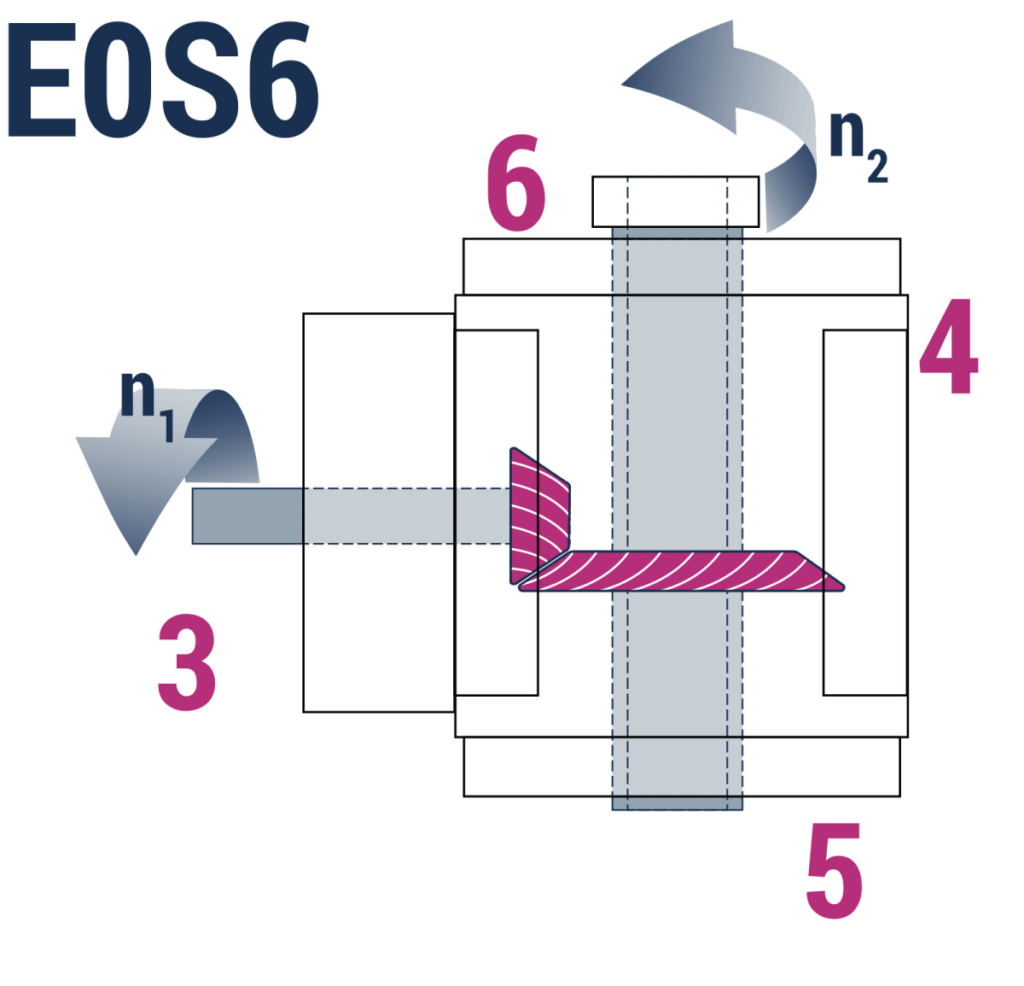

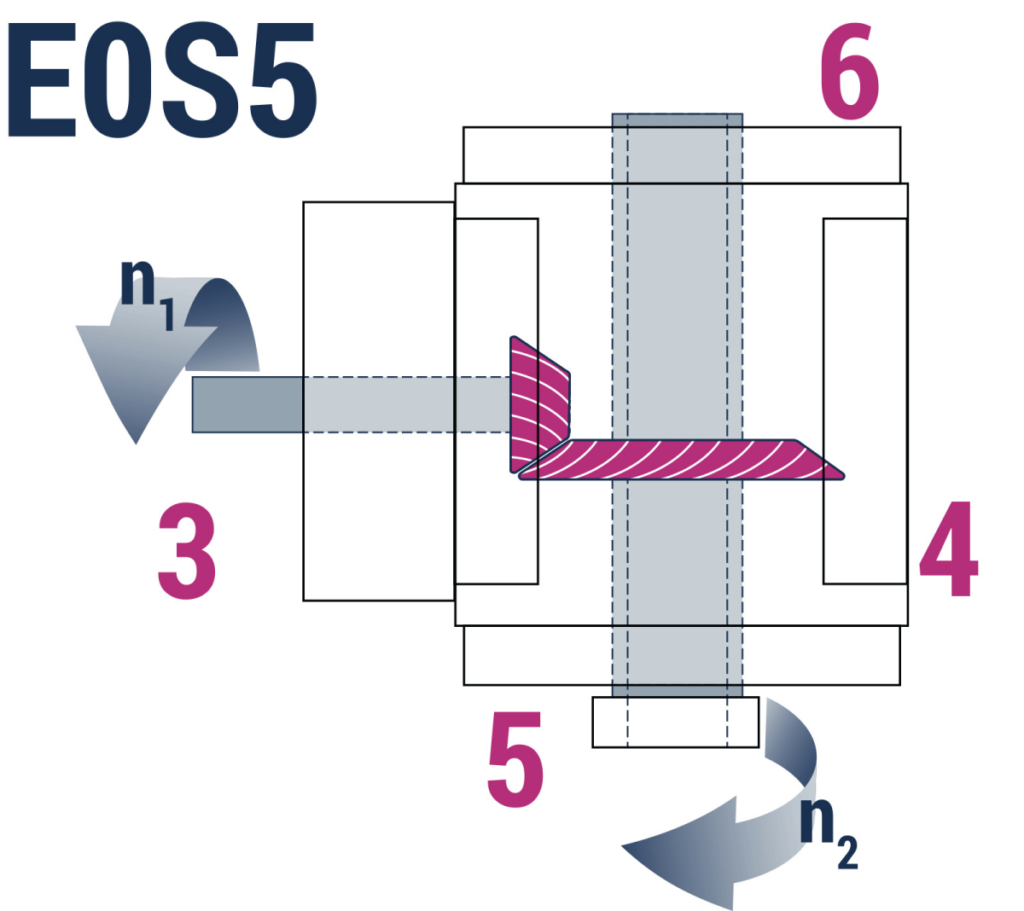

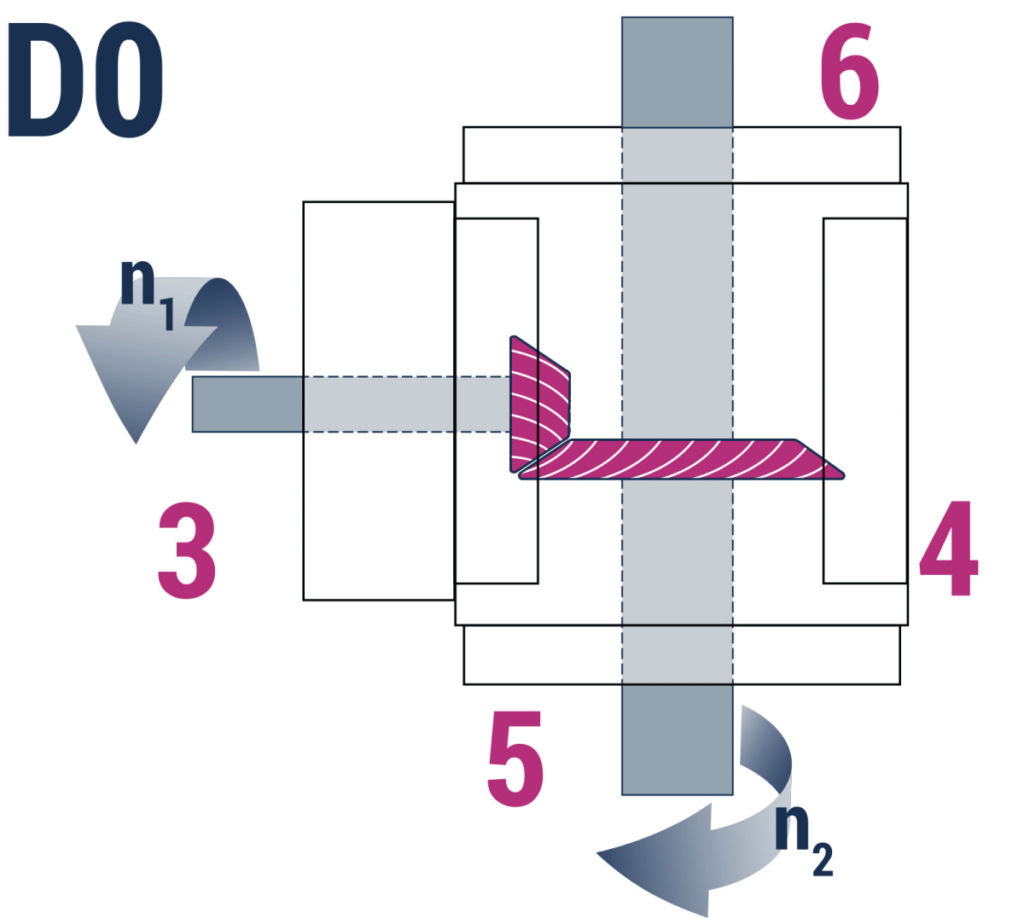

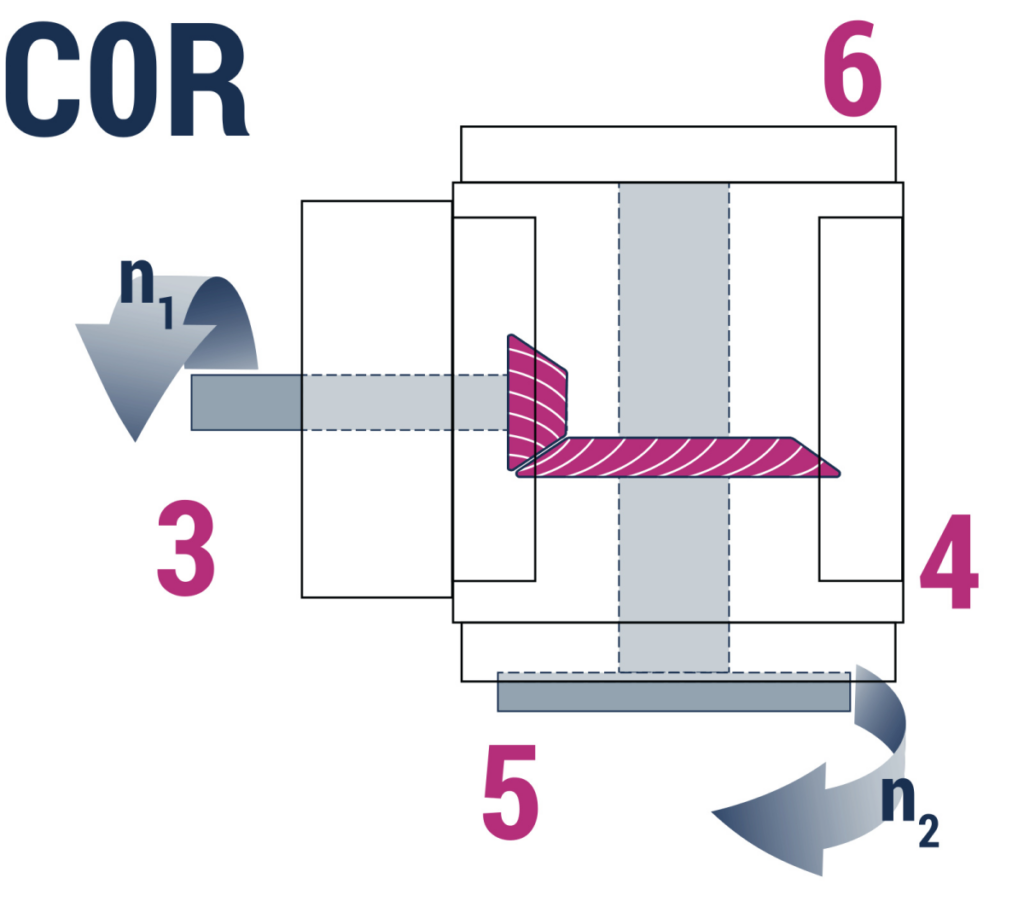

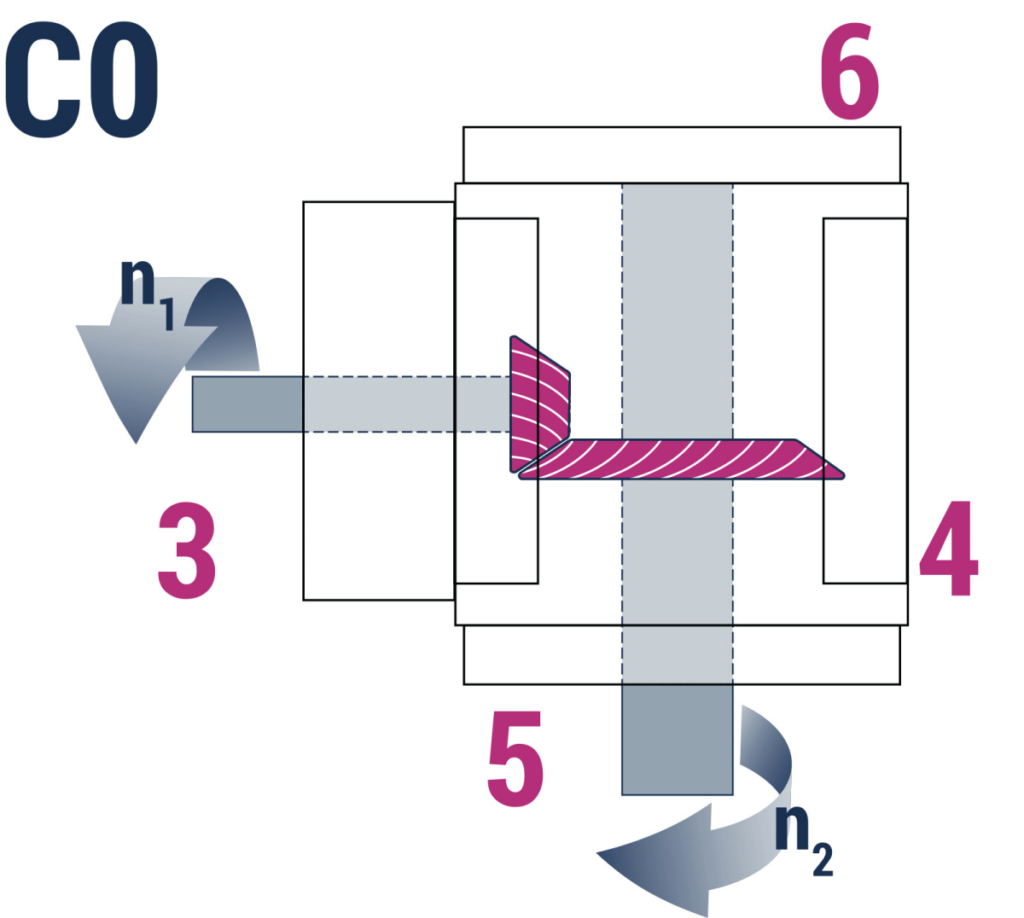

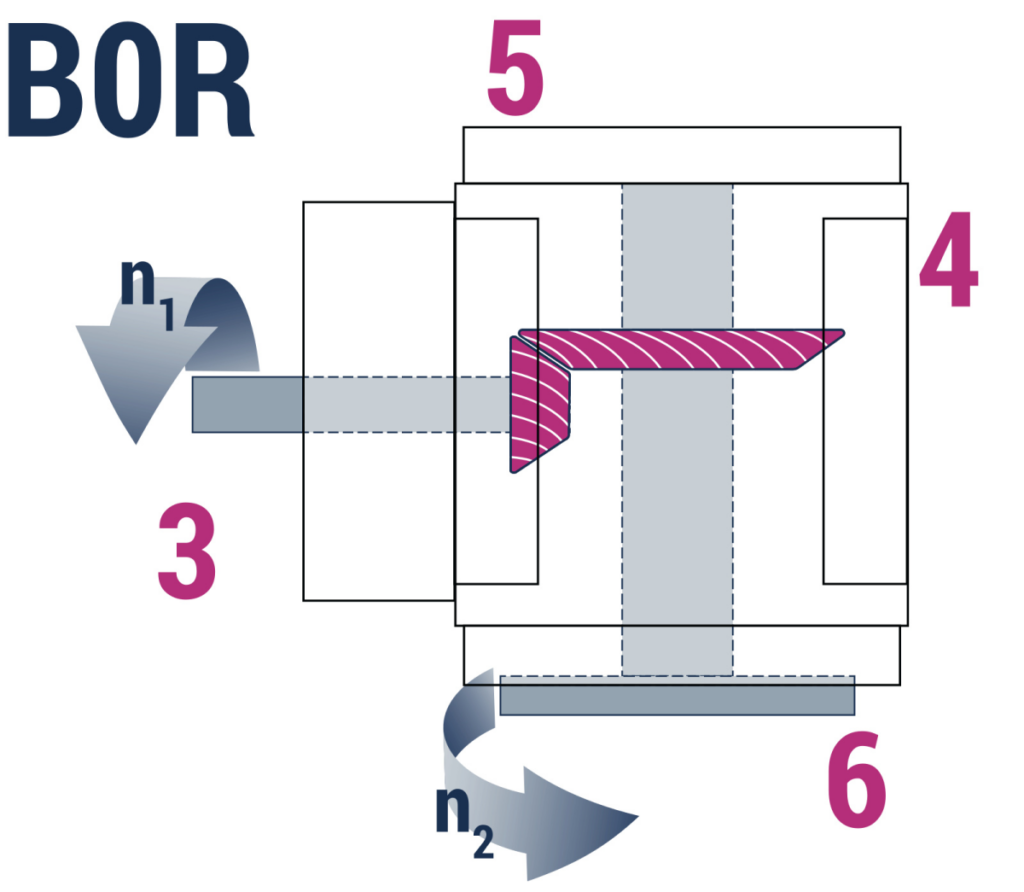

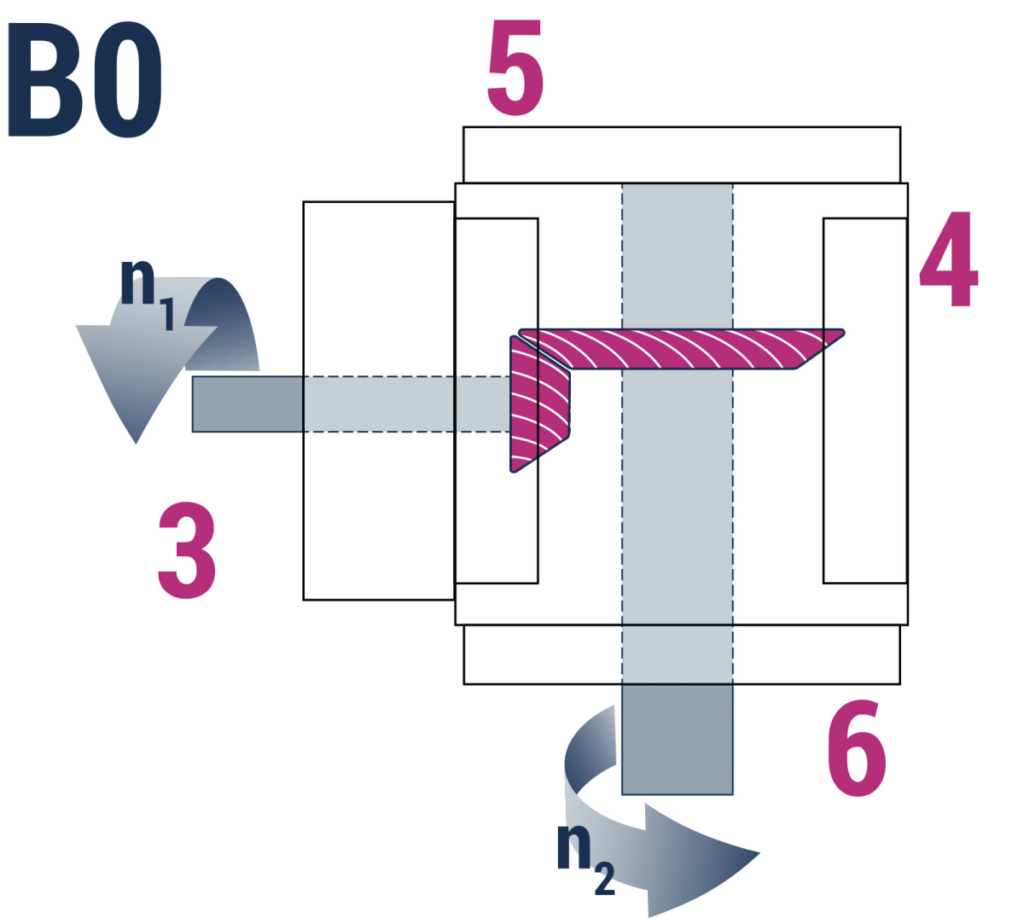

- Achsversatz zwischen An- und Abtriebswelle

- 6 Getriebegrößen von 090 bis 260 mm Kantenlänge

- Spielarm in der Ausführung < 4 Winkelminuten möglich

- Gehäuse aus Aluminium